Check out

Wastewater treatment products

Domestic Wastewater Treatment

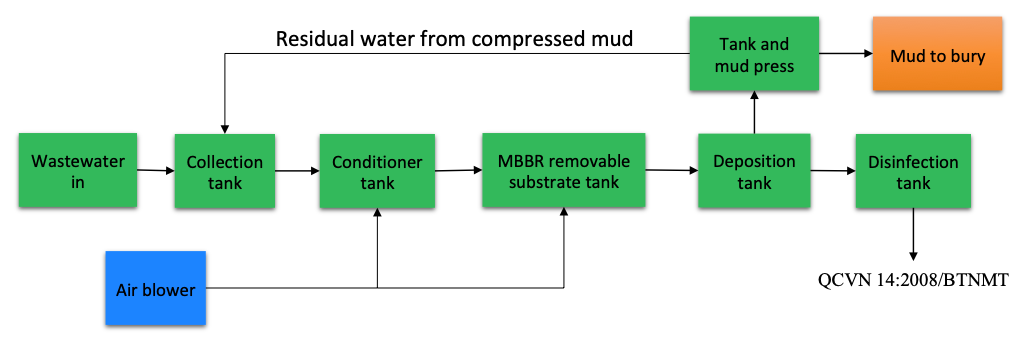

Domestic Wastewater Treatment Using MBBR Technology

MBBR (Moving bed bioreactor) wastewater treatment technology: It is an activated sludge technology that applies the microorganism technique to adhere to the moving material layer. Due to the use of microorganism material so the microorganism density (MLVSS) in the treatment tanks is higher than the activated sludge dispersion technique. The microorganism substrate used in this technology is a removable buffer substrate with a very large surface area, always moving in the tank so that it can make the most of the surface area of the microbiological substrate, so that the organism density in MBBR treatment facilities are very large, besides the moving substrate increases the ability to dissolve oxygen into water, which makes the treatment efficiency of this technology much higher than other technologies.

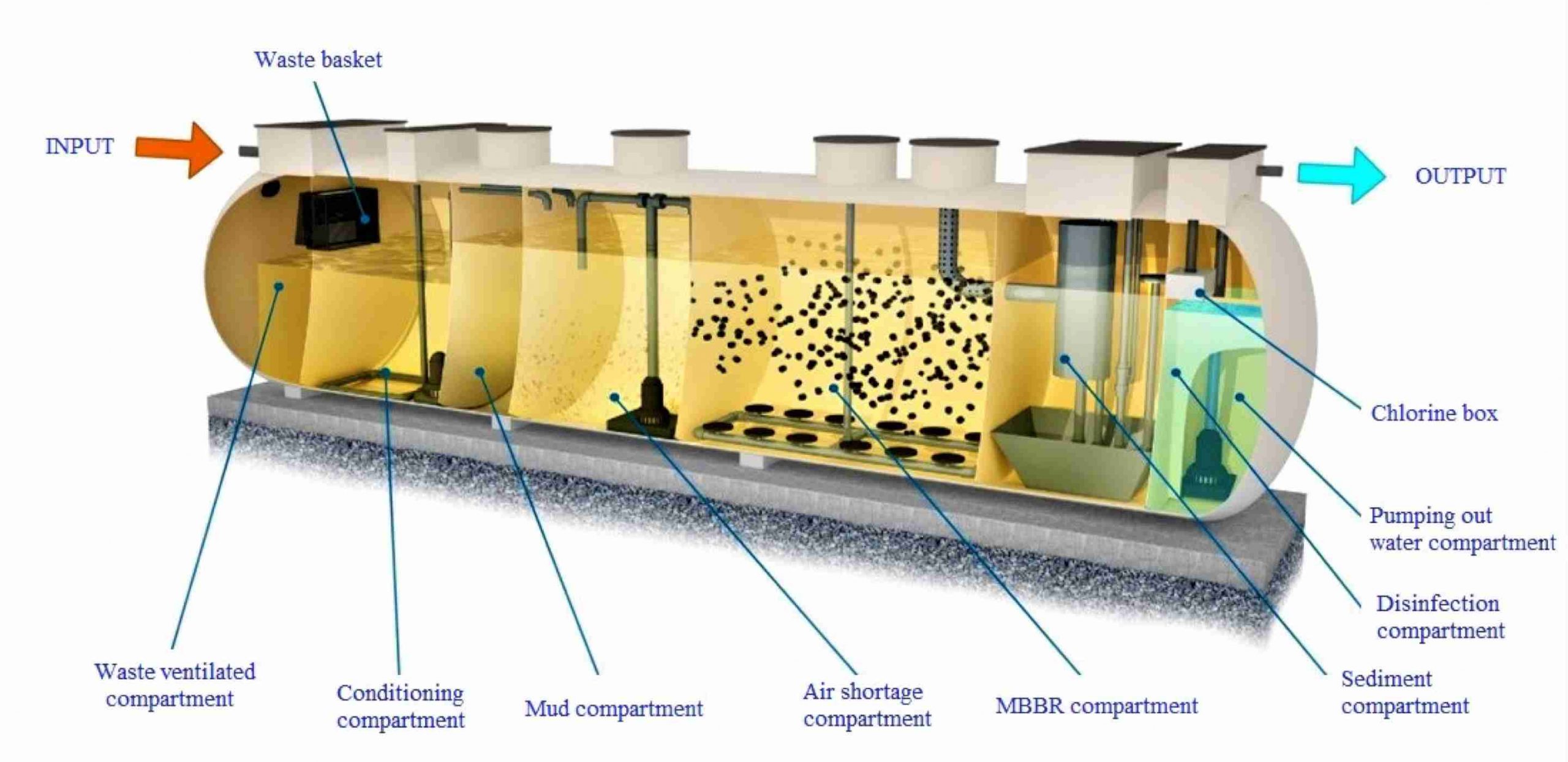

Inside of the MBBR Wastewater Treatment Technology

Water enters from this input and collects it in the ventilation tank. Drainage removes the mixed dust in the trash and passes through a conditioner tank, a mud tank, and an air shortage tank. After that, the wastewater is removed from the organic substances in the MBBR biological treatment tank and enters the sediment tank. Next, the wastewater is disinfected in the disinfection tank by the chlorine box. Finally, the detoxified water is pumped out by the pump.

Construction Images

This is an image of the appearance of MBBR wastewater treatment technology and its installation work.

Advantages of MBBR

This is a summary of the merits of this MBBR wastewater treatment system. From a technical point of view, there are Japanese technologies and high technologies such as low sludge content and full function in a block with a low microbial density per unit volume. Quality is recognized in many countries around the world. It is designed to be easy to use and easy to use. In terms of price, there are low investment costs and low operating costs. Maintenance is also simple. In terms of environment, this wastewater treatment system was designed with consideration for the environment, so it meets the strict environmental standards. In particular, it has a high BOD treatment efficiency and odorless wastewater treatment equipment, and can also be improved to AAO technology to completely treat nitrogen, phosphorus and other residual compounds.

Medical Wastewater Treatment

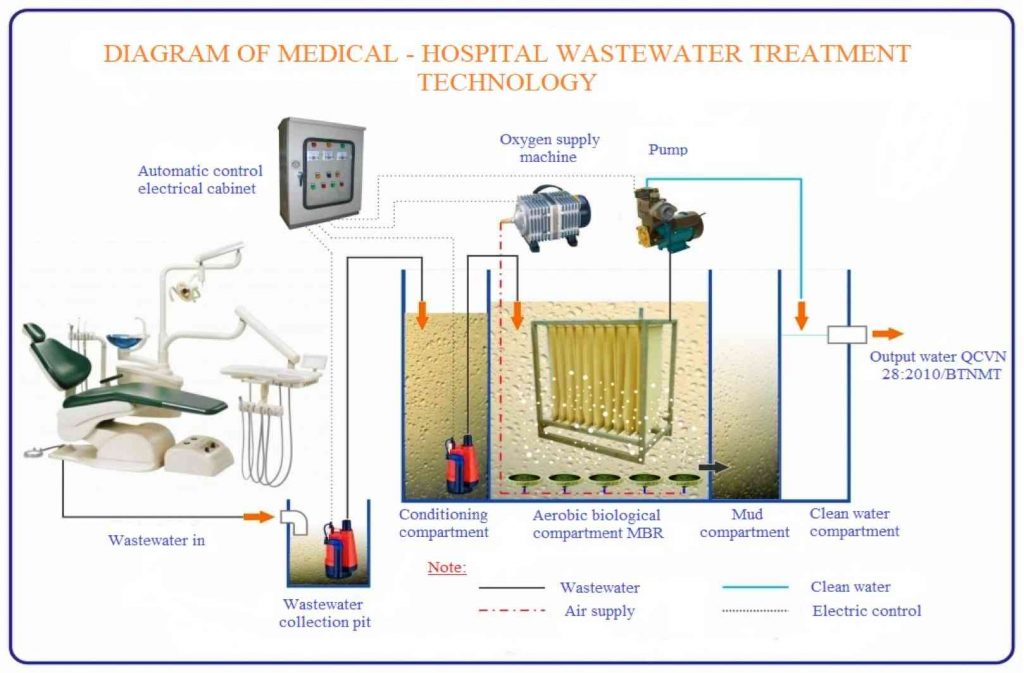

Medical Wastewater Treatment by MBR Filter Membrane Technology

MBR (Membrane bioreactor) technology: It is understood as a tank or wastewater treatment biological equipment which applies the dispersive activated sludge technique combined with MBR filter with very small size of MBR membrane (0.01 ~ 0.2 µm) so biological mud will be retained in the tank, high microbial density and increased treatment efficiency. This technology is strongly applied recently in the world and about 5 years ago in Vietnam.

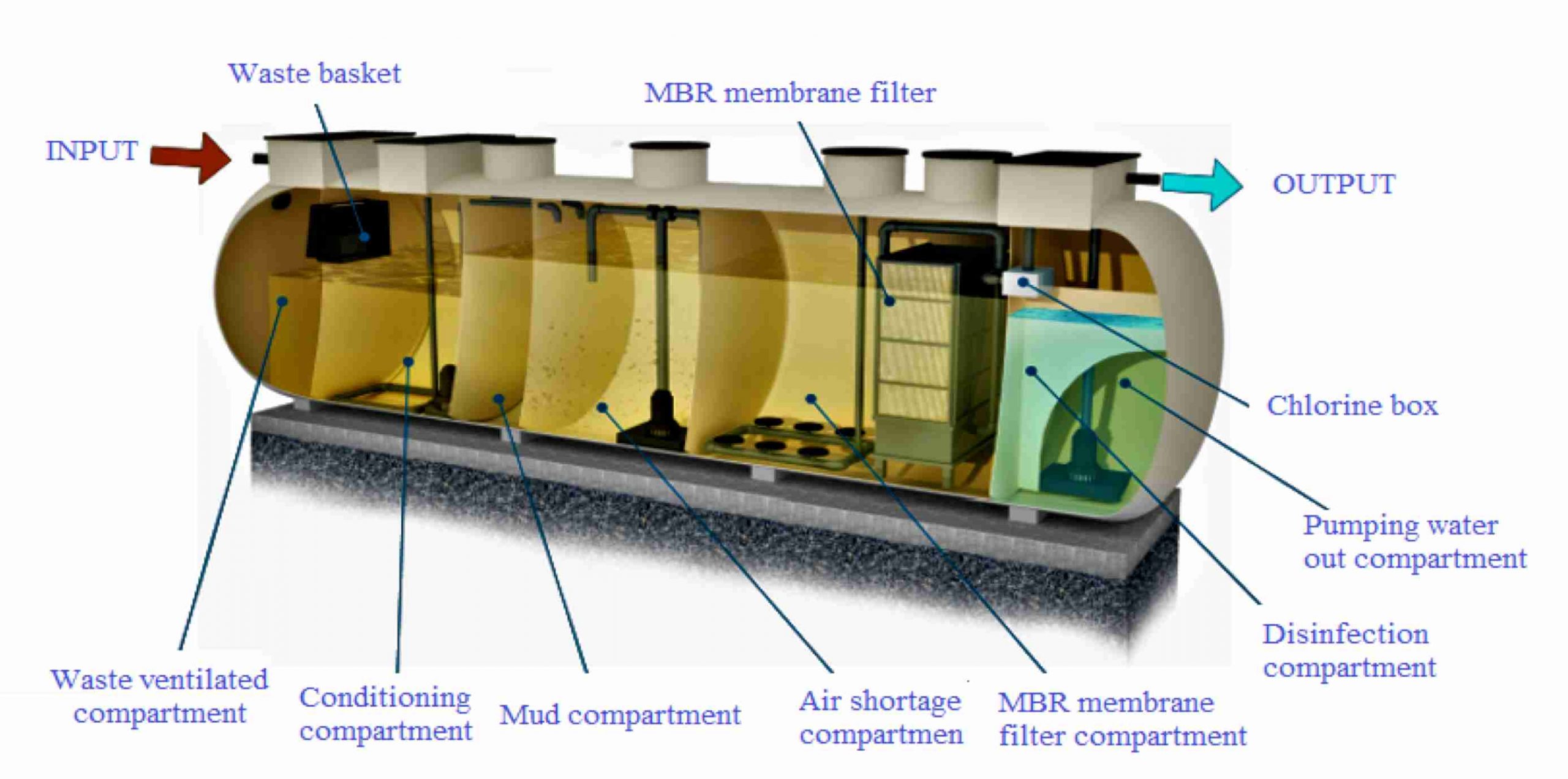

Inside of the MBR Wastewater Treatment Technology

Water enters from this input and is temporarily collected in the ventilation tank. Drainage removes the mixed dust in the trash and passes through a conditioner tank, a mud tank, and an air shortage tank. After that, the wastewater is microfiltered by the MBR tank to forcibly separate the treated water and the activated sludge. Next, the waste water is disinfected in the disinfection tank by the chlorine box. Finally, the detoxified water is pumped out by the pump.

Some Installation Pictures

This is an image of the appearance of MBR wastewater treatment technology and its installation work.

Advantages of MBR

This is a summary of the merits of this MBR wastewater treatment system. From a technical point of view, there are Japanese technologies and advanced technologies such as high degree of automation, space saving and easy installation, and the ability to move between places as needed. Quality is recognized in many countries around the world. It is designed to be easy to use and easy to use. In terms of price, it has a low operating cost. Maintenance is also simple. In terms of environment, this wastewater treatment system was designed in consideration of the environment, so it meets high standards compared to Vietnam standards. In particular, the treated water can be reused for floor cleaning and watering plants.

Wastewater Treatment For Industrial Zone

Depending on each manufacturing industry, this wastewater composition will have its own characteristics:

Food industry: BOD, suspended solids, toxic pesticides, growth hormone, material color, acid or alkali, etc...

Iron and steel industry: gasification products: naphthalene, benzene, cyanide, ammonia, phenol, cresols, anthracene, ... pollutants: animal fats and oils, solid particles, sulfuric acid, hydrochloric acid, ... these are all are substances arising during the firing, manufacturing, cleaning and surface treatment.

Paper and pulp industry: TSS, BOD, chloroform, furan, dioxin, phenol, COD and suspended solids.

Industrial oils: Including areas such as car wash, fuel storage, factories, transportation centers, power plants, ... wastewater from these areas contains: solvents, oils oily, grit, detergent and hydrocarbon.

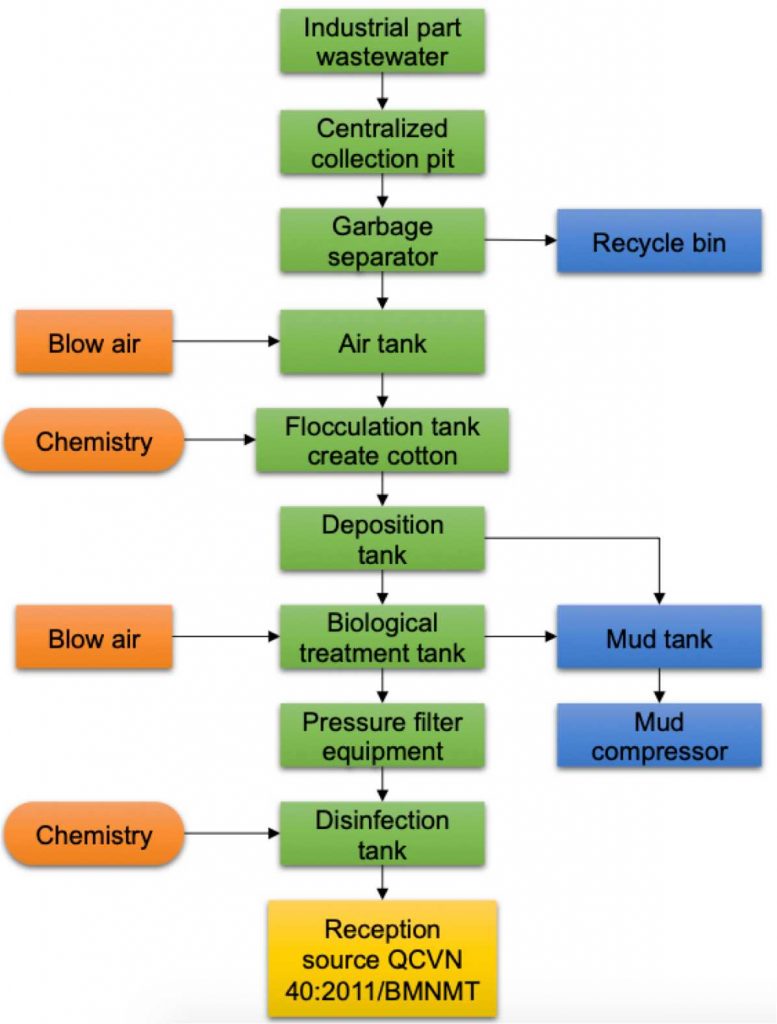

Images of Industrial Wastewater Treatment System

This is an image of the installation work of the industrial wastewater treatment system.

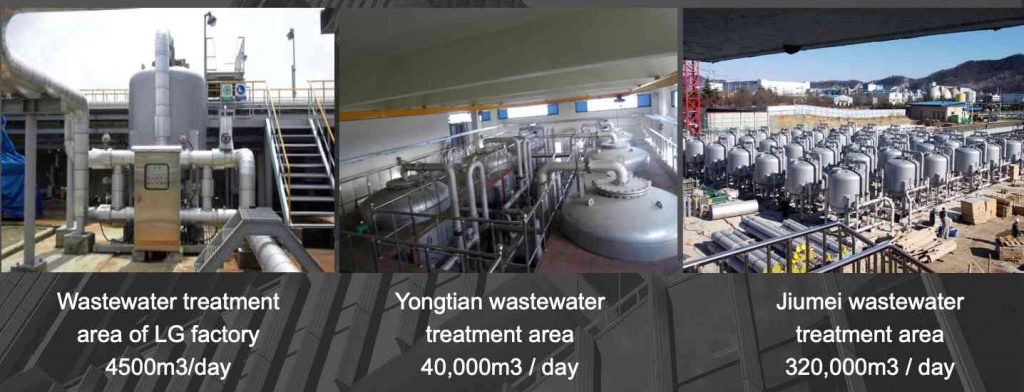

And this is the industrial wastewater treatment system installed in the LG factory and the Yongtian and Jiumei industrial zones in China.

Advantages of Our Industrial Wastewater Treatment

This is the summary of the merits of this industrial wastewater treatment system. From a technical point of view, there are Japanese technologies and advanced technologies such as rapid implementation and installation, treatment of pollutants using available microorganisms in wastewater. We also assure the quality, proper type of processing equipment and market reputation. The operation is automated. In terms of price, we designed the investment cost to match the actual requirements. The system is easy to maintain. In terms of environment, this wastewater treatment system was designed in consideration of the environment, so it is a safe and environmentally friendly system.