Check out

Incinerator products

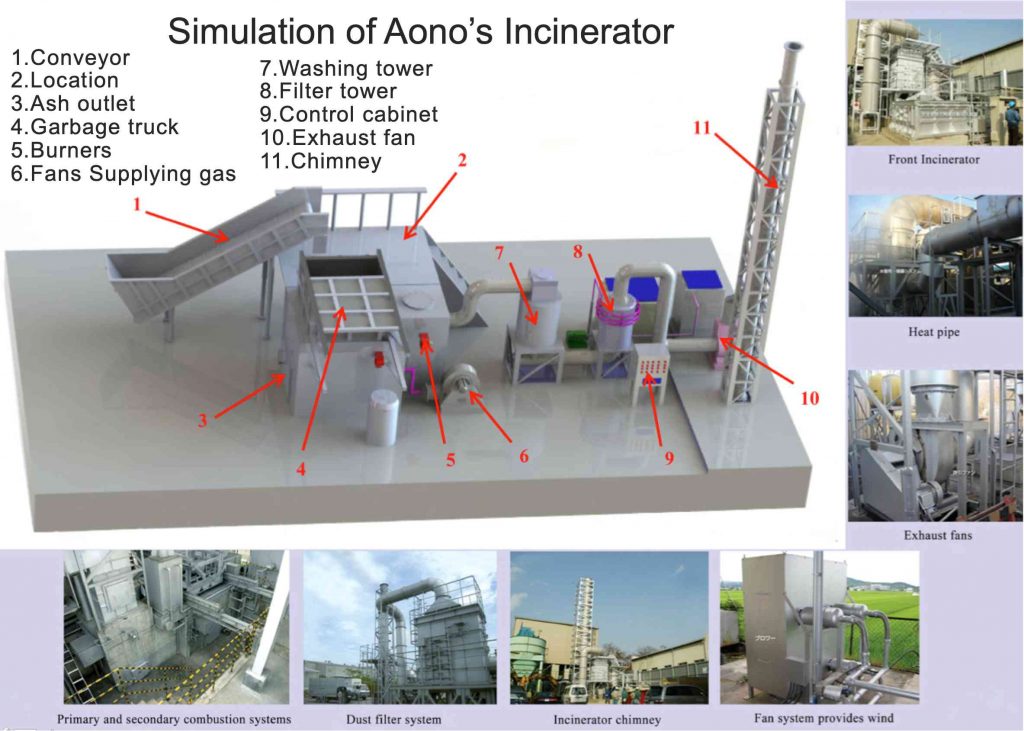

Simulation of Aono’s Incinerator

The external structure is composed by 1.Conveyor, 2.Location, 3.Ash outlet, 4.Garbage truck, 5.Burners, 6.Fan supplying gas, 7.Washing tower, 8.Filter tower, 9.Control cabinet, 10.Exhaust fan and 11.Chimney.

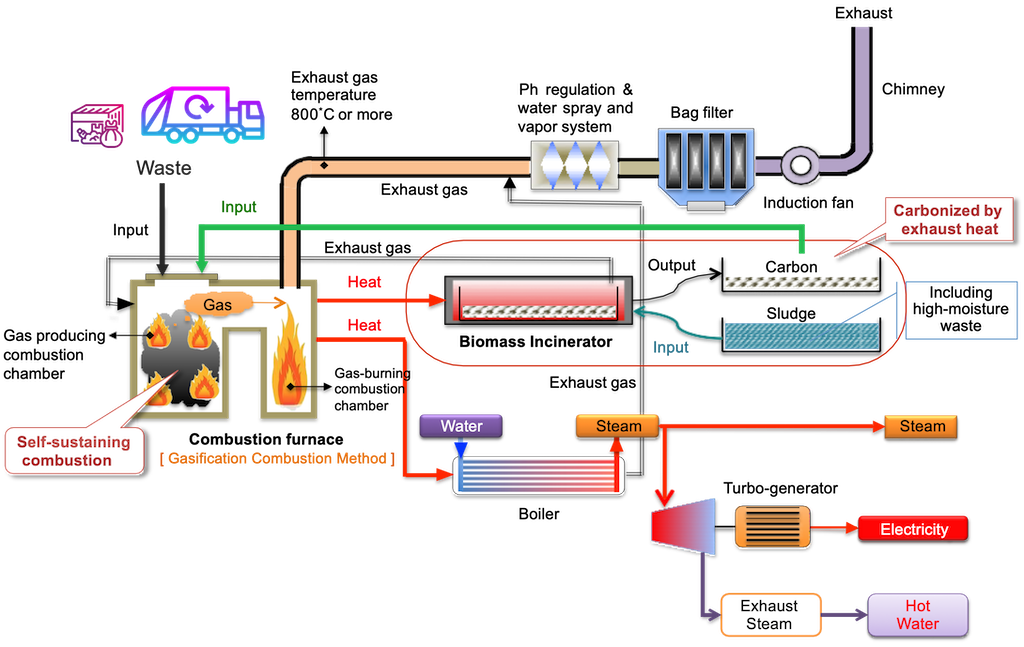

Inside of the Incinerator System

As for the inside of the incinerator system, as shown in the slide below, the waste that is injected from here, will generate gas while being incinerated by the primary combustion chamber. The generated gas is also burned by the secondary combustion chamber. This combustion method is called gasification combustion method. This combustion system boasts overwhelming combustion efficiency and safety like the combustion system of a steam locomotive. The generated exhaust gas at 800°C or higher enters the washing tower. After cleaning and cooling by adjusting the pH or spraying water, the gas will be detoxified by the bag filter and then discharged to the outside.

In addition, we are able to collect the generated heat, so-called waste heat, and provide a thermal energy reuse system such as a boiler, dryer system, industrial waste liquid combustion system and electricity generation system.

Incinerator AT-250

This is the operating of the incinerator AT-250, which can actually incinerate 10 tons of waste per day. Garbage is carried by the conveyor to the garbage truck. When the garbage is full, close the lid and burn it in the primary combustion chamber. This is the secondary combustion chamber. Next is the washing tower, and then the bag filter and chimney. This is a circulating cooling water system that does not emit any drainage. This system has been developed with the aim of becoming a smoke-free, odorless and pollution-free incinerator in consideration of the environment.

Achievement

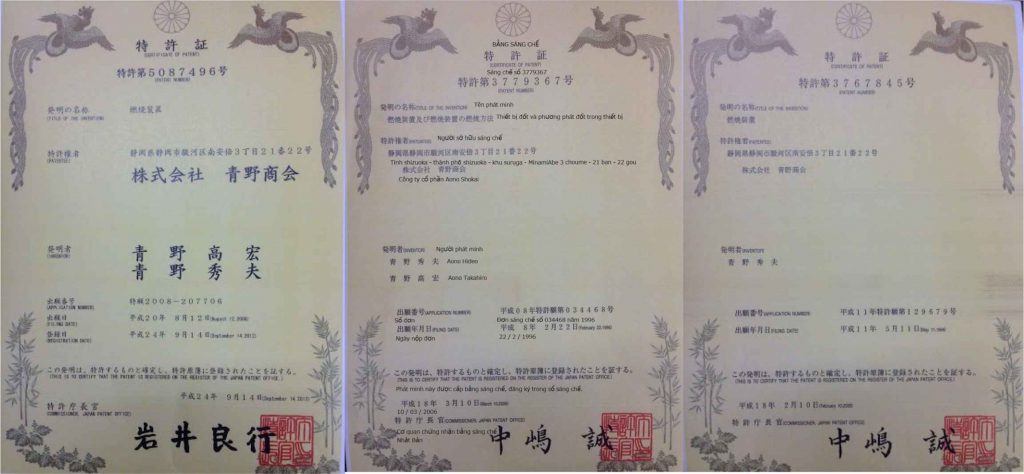

To date, we have over 50 years of experience in manufacturing incinerators. We have obtained 12 patents for incinerator and wastewater treatment technology from the Ministry of Science and Technology of Japan. It conforms to the exhaust gas of international standards and is so-called no pollution. Since installing the first incinerator in 1964, the Aono incinerator has already achieved international standards. Since 1990, we have expanded our business to 3R technology and developed the solution of “waste to energy”. And so far, we have exported and installed in many countries around the world.

Patents for Incinerator

The patents are those granted by the Ministry of Technology and Science, Japan, which relating to the invention of combustion equipment and combustion methods.

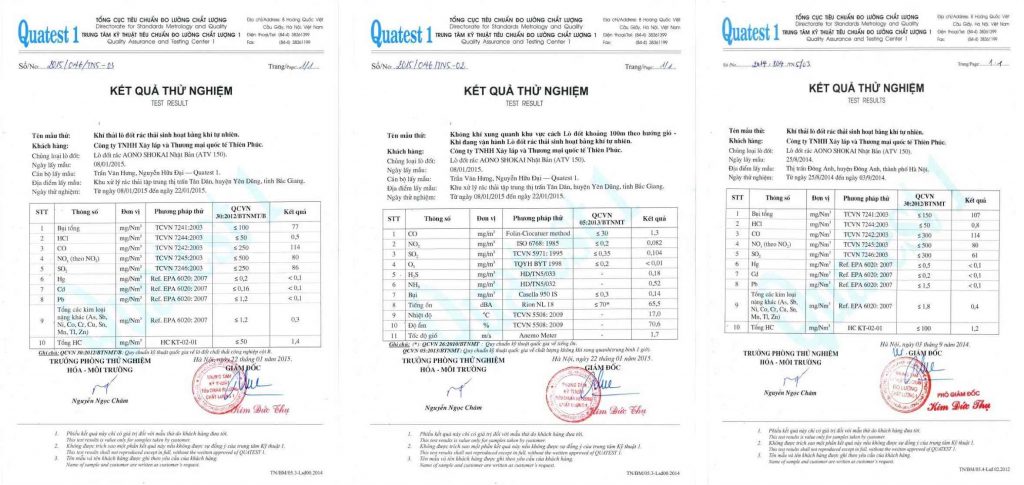

Exhaust Gas Test Results

As a result of the exhaust gas test of this incinerator, it has cleared the standard value of Vietnam in general waste as well as in medical and industrial systems.

Experience construction in Vietnam and Laos

Many customers have purchased this incinerator in Vietnam so far. Among them, Japanese companies were Honda, Showa, Yamaha, and Nitori. Last year, we also purchased from HOYA in Laos.

1996: Installation the 1st industrial waste incinerator in Honda Vietnam factory.

2003: Installation the 2nd industrial waste incinerator in Honda Vietnam factory.

2006: Installation the waste incinerator in Showa Vietnam factory.

2008: Installation the industrial waste incinerator in Yamaha Vietnam factory.

2010: Installation the industrial waste incinerator in Nitori Vietnam factory.

2013: Installation the 3nd industrial waste incinerator in Honda Vietnam factory.

2019: Installation the industrial waste incinerator in HOYA Laos factory.

In addition, our system are installed in many provinces and cities in Indochina area.

Aono Incinerator Installed at Various Factory

This is the incinerator that was installed in 2003 at the Honda Vietnam factory.

And this is the incinerator that was installed at the HOYA factory in Vientiane, Laos last year.

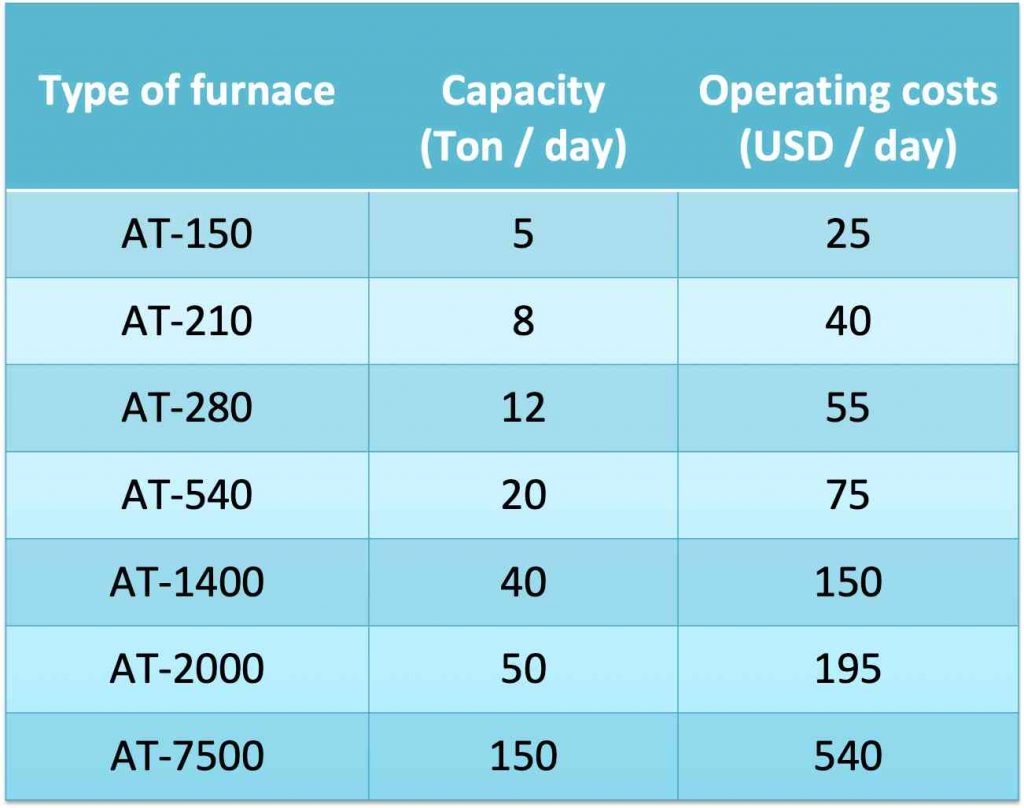

Low Operating Costs

Another advantage of the Aono incinerator is low fuel consumption. This is the result of calculation including electricity, fuel and labor costs. For example, if you incinerate 5 tons of waste a day, it costs just $25 to operate. The reason for realizing the low fuel consumption is that the combustion method is the gasification combustion method. "Gasification combustion method" is a combustion method in high efficiency self-burning. Compared to a general incinerator that uses many burners, the Aono-type burner has an auxiliary role of ignition and uses very little fuel. In other words, it uses almost no fuel to incinerate the waste.

Advantages of Aono Incinerator

This is the summary of the merits of this incinerator. From the technical point of view, there are advanced technologies such as Japanese technology, gasification incinerator system, reusing of combustion energy and ceramic bag filter. Quality is recognized in many countries around the world. It is designed to be easy to use. In terms of price, it has low investment cost and low operating cost. Maintenance is also simple. In terms of environment, this incinerator was designed with consideration for the environment, so it complies with strict environmental standards. In particular, there is no emission of dioxins or nitrogen oxides and no water pollution.

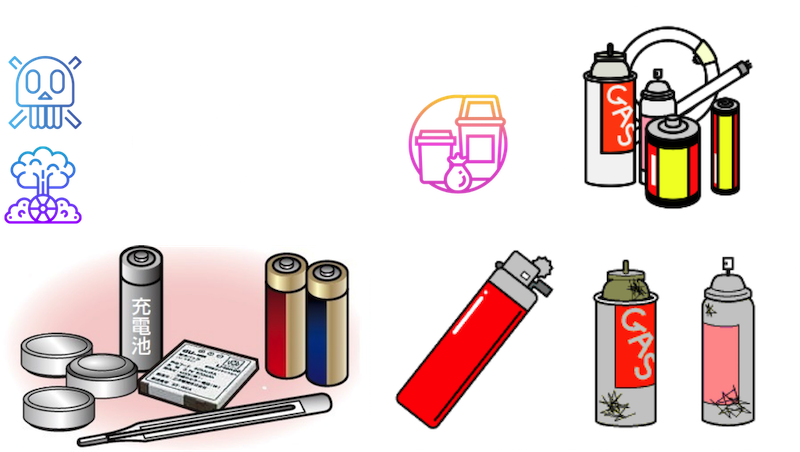

Dangerous Garbage

This incinerator can incinerate various industrial wastes. Among them, dangerous waste such as battery, mercury thermometer, fluorescent lamp, gas lighter and spray can is explosive. I would like you to avoid putting it in.

Do you need more?

Check our solutions

Professional IT services

Check the full range of our IT services.

Professional GreenTech services

Check the full range of our GreenTech services.